HIGH DENSITY CARTRIDGE HEATERS

people are viewing this right now

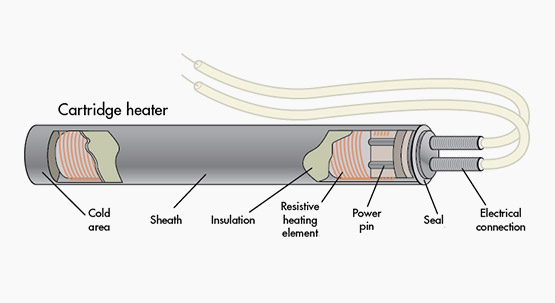

JB Heaters’ High Density Cartridge Heater is a versatile “component heater” designed for a wide range of applications. Commonly used in molds, dies, and sealing bars, these cartridge heating elements are designed to fit snugly inside a cavity, efficiently heating solids by reaching high temperatures. One key feature is the ability to incorporate a built-in thermocouple, allowing for more precise temperature control.

The High Density Cartridge Heater comes in various diameters, making it suitable for any cavity. It can be custom-designed with specific cold sections, and lead wires extend from the heater to connect to your controls.

What sets the High Density Cartridge Heater apart is its high compression, which enables efficient heat transfer. Each unit is produced with a ground surface to achieve a precise H7 fit, ensuring optimal thermal performance.

-

Free worldwide shipping on all orders over $100

-

Delivers in: 3-7 Working Days Shipping & Return

Reviews

There are no reviews yet.